-

ACCIONA and innovation

ACCIONA and innovationWE MAKE PROJECTS A REALITY THAT HELP THE PROGRESS OF SOCIETY AND RESPECT FOR THE ENVIRONMENT

-

Challenges

ChallengesDO YOU HAVE AN IDEA OR PROJECT?

- LAUNCH YOUR PROPOSAL

Funded under the 2023 “Transmisiones” call by CDTI–AEI, ACCIONA is coordinating INARTRANS 4.0, “Digital transition toward an advanced industry in artificial intelligence solutions for the transport infrastructure sector,” a project that aims to drive the adoption of AI solutions in transport infrastructure to accelerate digital transformation and increase the competitiveness of the construction sector. This effort will be applied across the entire infrastructure value chain—construction, operation and maintenance—with a strong focus on information systems and data governance. The project involves the companies INDRA, AZVI, VIRTUALMECH and JIG, and the technology centers CTCON, TEKNIKER, INTROMAC, UAH and UPM.

But how can AI improve decision-making throughout the entire life cycle of a rail infrastructure asset?

This article presents the solutions the consortium is developing for each phase in the life of an infrastructure asset.

Construction

First, INARTRANS incorporates and develops new technology that helps digitalize key aspects during tunnel construction and earthworks associated with railway sections.

Tunnel construction—both with TBMs and using conventional methods—still has limitations that can be addressed through machine learning and artificial intelligence models. In INARTRANS, with a sufficient volume of real data, the main excavation and geological parameters are analyzed by connecting to the TBM’s real-time database. From more than 7,000 variables, 23 have been selected from TBM sensors, along with 4 parameters to define the geotechnical units.

By building regression models (geology–machine), it is possible to predict TBM advance in terms of parameters relevant to machine control, informing the operator’s decisions for optimal progress under safe conditions and within the machine’s operating ranges. The model is trained and calibrated with real TBM excavation data, comparing actual excavation results with the model outputs. This enables the operator to obtain optimal operating values to apply while driving the TBM, improving penetration in any type of ground.

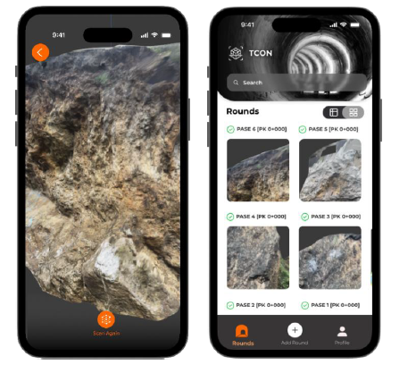

Second, for tunnels excavated using conventional methods, a tool is being developed to perform automated geological mapping using only a smartphone, through image capture and LiDAR scanning, to obtain a numerical output of geomechanical quality.

In addition, based on this result, the over-excavation caused in the cross-section is predicted and a blasting plan is recommended in line with the optimal values. This tool uses artificial intelligence algorithms for image feature recognition and prediction based on machine learning models trained with real data.

Another disruptive element is automated construction monitoring through image processing and sensorization for earthmoving. Currently, it is possible to install CCTV systems or IP cameras to view work units from a control room, but these systems lack intelligence and do not allow the use of the data captured in the images—unlike other domains such as traffic monitoring or access control at transport stations. INARTRANS will implement this functionality on its platform to analyze data from earthmoving tasks and propose optimized plans and routes based on real-time and historical data.

Operation and maintenance

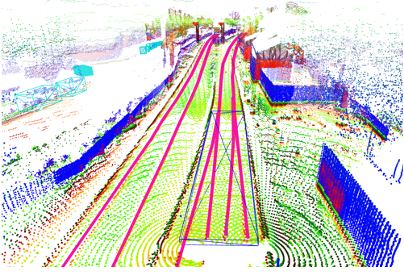

Railway operation and maintenance face a wide range of challenges that are currently being addressed using enabling technologies to cover longer inspection distances in less time and with high precision. INARTRANS contributes advanced sensors, automated data capture and interpretation, and the creation of digital twins to provide an in-depth understanding of the condition of both infrastructure and rolling stock.

So, specifically, what techniques are being applied? The models being deployed include:

• AI/ML-based models that improve operations and maintenance, focused on managing railway O&M through intelligent image processing to characterize various parameters of rolling stock and cargo as they pass specific points along the infrastructure; determining different rail parameters via the deployment of smart sleepers that provide critical information for operations and maintenance at key locations; and improving rolling stock positioning as well as effective train length and train integrity.

• Hybrid predictive models for catenary evolution: AI/ML algorithms trained on real datasets (depending on their volume, quality and availability) and synthetic datasets. To generate these synthetic datasets, physical digital twins will be developed based on multibody vehicle simulations, physical infrastructure

End-to-end data management platform

How is data managed from the moment it is captured by IoT sensors until it is used in digital twins and decision dashboards?

To ensure that the results achieved through AI models can be directly applied by future users, a platform has been designed to control construction, operation and maintenance processes via real-time digital twins and dashboards.

The core technological contribution lies in an IT infrastructure that enables the secure management and exploitation of large volumes of data from multiple external sources in heterogeneous, complex formats. To this end, a common ontology and architecture have been defined to guarantee data messaging, storage, transformation and representation in dashboards or digital applications.

This infrastructure is structured as a multilayer system (Local–Edge and a central Cloud node), vertically integrated through Communication Middleware (CMV), and supports data processing via ETL engines and dashboards.

All AI solutions under study in this project are deployed over this infrastructure, along with intelligence embedded in the infrastructure itself.